0523-87962976

-

Home

-

About Us

-

Products

- TDS Series Co-rotating Twin Screw Extruders

- TDY Series Couter-rotating Twin Screw Extruders

- TDS/TDD Series Two Stage Extruders

- TDD-P Series Venting Single Screw Extruders

- TDW Series Reciprocating Single Screw Extruders

- Plastic Sheets/Plates/Films Extrusion

- Raw Material Dealing System

- Compounding Extrusion Units

- Pelletizing Units

- Spare Parts

- Electrical Control Cabinet System

- TDS Series Co-rotating Twin Screw Extruders

-

News

-

Contact Us

-

-

Home >

-

About Us >

-

Products >

- TDS Series Co-rotating Twin Screw Extruders

- TDY Series Couter-rotating Twin Screw Extruders

- TDS/TDD Series Two Stage Extruders

- TDD-P Series Venting Single Screw Extruders

- TDW Series Reciprocating Single Screw Extruders

- Plastic Sheets/Plates/Films Extrusion

- Raw Material Dealing System

- Compounding Extrusion Units

- Pelletizing Units

- Spare Parts

- Electrical Control Cabinet System

-

News >

-

TDS Series Co-rotating Twin Screw Extruders

Technical Characteristic

◆ Both screws and barrels designed according to building block principle. And the machine’s extensive performance and special purpose could be achieved ideally.

◆ Host series specifications

¢20mm — ¢200mm TDS series extruders model-was clearly defined A, B ,C, D series according to different rotary speed and torque class

◆Plasticizing, compounding units

Screw elements with closely intermeshed design have excellent self-wiping and interchangeable characteristics

Screw elements combined with spline shaft to achieve higher torque and large screw channel volume.20 years know-how in screw design makes new type screw elements and screw plan supplied, in order to satisfy specific requirements of each process.

◆ Power transmission system

The newly designed torque distribution system, high precision grinding of hardened gear teeth, imported high quality key bearing, and the interlocking of lubrication system are among the reasons for the good reliability of Norda’s products.

Imported transmitters with high torque output and torque limitter are optional.

◆ Material

The material of extruder depends on different process-material properties.

◆Extruders are all assembled on welding base,and special pads equipped for adjustment.

◆ Stainless steel covers equipped for barrels to keep heat preservation.

◆ Basket screen changer, plate-type screen changer and non-stop screen changer are available.

TDS Technical Data

Type | Series | D(mm) | L/D | n (r/min) | RPM (kw) | T(N.m) | T/A3 | Q (kg/h) |

TDS-20 | A | 22 | 32-64 | 400 | 3 | 30 | 4.8 | 2~10 |

B | 600 | 4 | 30 | 4.8 | 5~15 | |||

TDS-30 | A |

30 |

32-64 | 400 | 7.5 | 85 | 4.8 | 10~30 |

B | 600 | 11 | 85 | 4.8 | 10~40 | |||

C | 600 | 15 | 110 | 6.2 | 15~55 | |||

D | 600 | 18.5 | 140 | 8 | 30~75 | |||

TDS-35 | A |

35.6 |

32-64 | 400 | 11 | 125 | 4.6 | 10~40 |

B | 600 | 15 | 115 | 4.2 | 15~55 | |||

C | 600 | 22 | 165 | 6.1 | 40~95 | |||

D | 600 | 30 | 225 | 8.3 | 70~120 | |||

TDS-40 | A |

41 |

32-64 | 400 | 22 | 250 | 6.0 | 40~95 |

B | 600 | 30 | 225 | 5.5 | 70~120 | |||

C | 600 | 37 | 280 | 6.8 | 90~150 | |||

D | 600 | 45 | 340 | 8.3 | 120~200 | |||

TDS-52 | A |

51.4 |

32-64 | 500 | 45 | 405 | 5.1 | 120~200 |

B | 600 | 55 | 415 | 5.2 | 155~255 | |||

C | 600 | 75 | 565 | 7.1 | 200~355 | |||

D | 600 | 90 | 680 | 8.5 | 255~400 | |||

TDS-65 | A |

62.4 |

32-64 | 500 | 75 | 680 | 4.8 | 200~355 |

B | 600 | 90 | 680 | 4.8 | 255~400 | |||

C | 600 | 110 | 830 | 5.9 | 300-550 | |||

D | 600 | 160 | 1200 | 8.5 | 500~850 | |||

TDS-75 | A |

71 |

32-64 | 500 | 110 | 995 | 4.6 | 300~550 |

B | 600 | 132 | 995 | 4.6 | 450~750 | |||

C | 600 | 160 | 1200 | 5.5 | 500~850 | |||

D | 600 | 250 | 1890 | 8.7 | 750~1250 | |||

TDS-85 | A |

81 |

32-64 | 500 | 200 | 1810 | 5.8 | 600~1000 |

B | 600 | 220 | 1660 | 5.3 | 650~1100 | |||

C | 600 | 280 | 2110 | 6.7 | 850~1400 | |||

D | 600 | 350 | 2640 | 8.4 | 1050~1750 | |||

TDS-95 | A |

93 |

32-64 | 500 | 250 | 2260 | 4.7 | 750~1250 |

B | 600 | 315 | 2380 | 5.0 | 950~1600 | |||

C | 600 | 450 | 3400 | 7.1 | 1350~2250 | |||

D | 600 | 550 | 4150 | 8.7 | 1650~2750 | |||

TDS-120 | A |

116 |

32-56 | 400 | 315 | 3570 | 4.4 | 950~1600 |

B | 500 | 450 | 4080 | 5.0 | 1350~2250 | |||

C | 500 | 550 | 4980 | 6.1 | 1800~3000 | |||

D | 500 | 750 | 6800 | 8.4 | 2700~4500 | |||

TDS-135 | A |

133 |

32-48 | 400 | 550 | 6200 | 4.4 | 1650~2750 |

B | 500 | 750 | 6800 | 4.8 | 2250~3750 | |||

C | 500 | 900 | 8100 | 5.7 | 3000~5000 | |||

D | 500 | 1200 | 10800 | 7.7 | 4500~7500 |

-

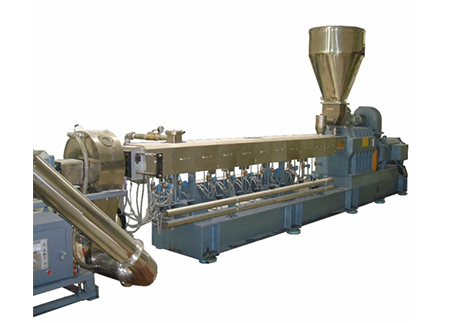

TDS-35 twin screw extruder

TDS-35 -

TDS-40 twin screw extruder

TDS-40 -

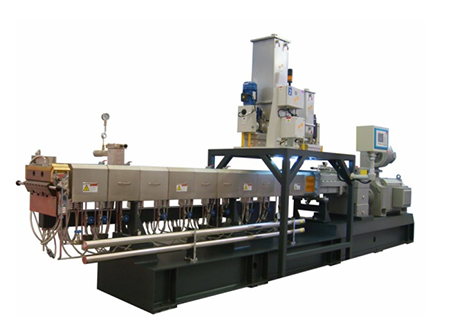

TDS-52 twin screw extruder

TDS-52 -

TDS-65 twin screw extruder

TDS-65 -

TDS-75B twin screw extruder

TDS-75B -

TDS-85B twin screw extruder

TDS-85B -

TDS-95B twin screw extruder

TDS-95B

- About Us

-

Products

- TDS Series Co-rotating Twin Screw Extruders

- TDY Series Couter-rotating Twin Screw Extruders

- TDS/TDD Series Two Stage Extruders

- TDD-P Series Venting Single Screw Extruders

- TDW Series Reciprocating Single Screw Extruders

- Plastic Sheets/Plates/Films Extrusion

- Raw Material Dealing System

- Compounding Extrusion Units

- Pelletizing Units

- Spare Parts

- Electrical Control Cabinet System

- News

-

contact us

Tel : +86-25-52471902

Tel : +86-25-52471902 +86-25-52885482

Fax : +86-25-52471902

Fax : +86-25-52471902 E-mail : [email protected]

E-mail : [email protected]  Add : No.212, Lantian Road, Lukou Street,

Add : No.212, Lantian Road, Lukou Street, Jiangning District, Nanjing, China (211113)

-

FOLLOW US

Follow us in social meida

Copyright © 2024 Nanjing Norda Extrusion Equipment Co.,Ltd. . All Right Reserved Friendly Link | Sitemap